煤系固废资源化利用

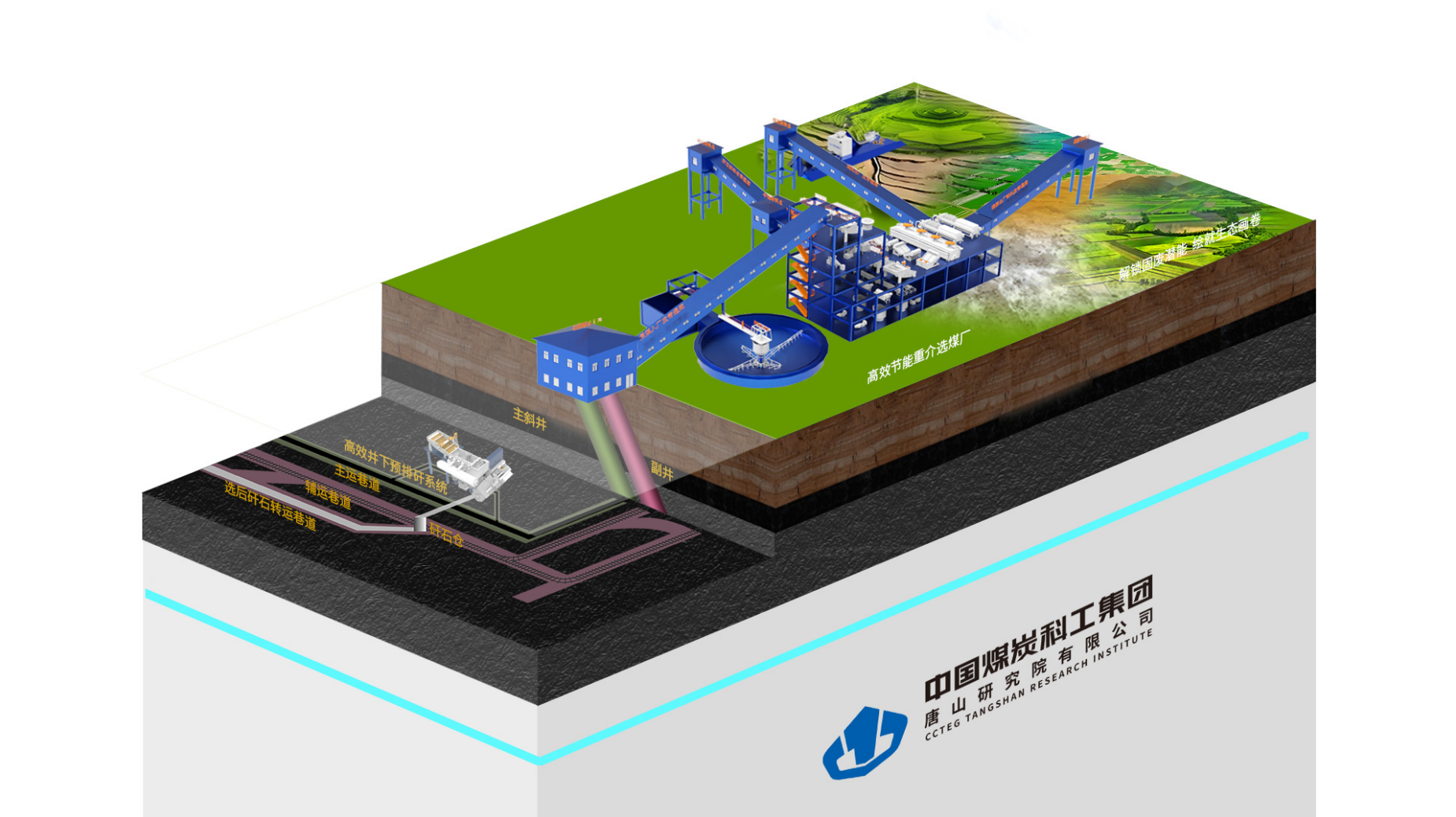

井下煤炭借助高效跳汰排矸系统,精准识别矿石特性,可从原矿中高效分离煤炭,大幅提升煤质。其中,6mm 以上矸石直接井下回填,显著节省运营成本;6mm以下部分则输送至选煤厂进行精深分选。分选后剩余的煤矸石与煤泥,经与生物菌肥科学配比,将其转化为滋养矿山的有机土壤。富含的营养成分可快速恢复矿山生机,最终实现植被繁茂、生态复绿的目标。作为全产业链综合服务商,以专业的技术、完备的设备、卓越的生态修复能力,为矿山企业量身定制发展路径,驱动矿业迈向绿色未来。

Underground coal is processed through a high-efficiency jigging refuse removal system that accurately identifies ore characteristics, enabling efficient separation of coal from raw ore and significantly improving coal quality. Among this, gangue larger than 6mm is directly backfilled underground, substantially reducing operational costs, while particles smaller than 6mm are transported to the coal preparation plant for further refinement. The remaining coal gangue and slime are scientifically blended with bio-bacterial fertilizers to transform them into organic soil that nourishes the mining area. The rich nutrient composition rapidly revitalizes the mined land, ultimately achieving the goal of lush vegetation and ecological restoration.

As an integrated full-industry-chain service provider, we tailor development pathways for mining enterprises with professional expertise, comprehensive equipment, and exceptional ecological restoration capabilities, driving the mining industry toward a sustainable future.

联系人:李德亮 联系电话:13933400926