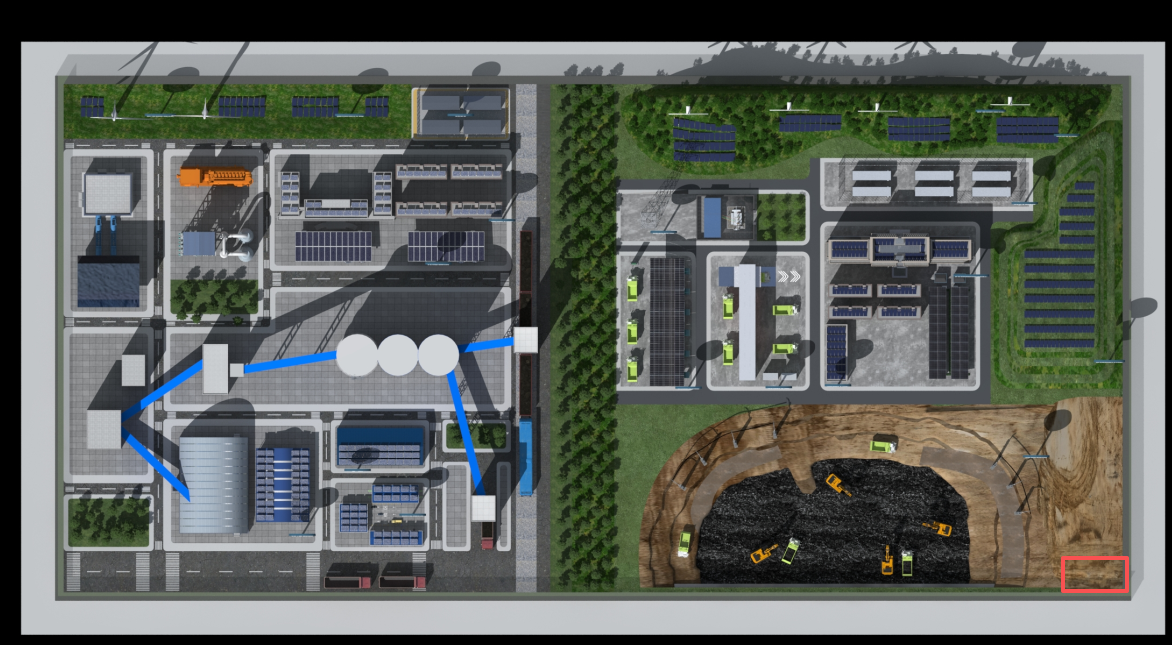

零碳矿山(井工、露天)建设方案

零碳矿山建设方案功能卓越且极具先进性。建设风光储用一体化系统,绿电利用率超85%,全电设备替代燃油设备并配自动充换电场站,电气化率≥95%。打造具备全生命周期电力系统管理、AI 能耗模型实时监测预警、数字孪生与多目标算法优化调度等功能的数字化能碳管控平台。井工矿重点开展采掘工作面用高效电驱掘进机、采煤机,存量机电设备节能改造,余热回收利用,全浓度瓦斯抽采综合利用,矿区新能源开发,运输清洁化改造等。露天矿重点开展采掘用电动挖掘机与光伏直供电自卸车,洗选通过智能干选系统降能耗等。多能互补智慧系统推动能源高效循环,全方位助力矿山零碳转型。

The construction plan for zero-carbon mines features outstanding functions and high advancement. An integrated wind-solar-storage-utilization system is built, with green electricity utilization rate exceeding 85%. All-electric equipment replaces fuel-powered equipment, equipped with automatic charging and swapping stations, achieving an electrification rate of ≥95%. A digital energy-carbon management and control platform is developed, with functions including full-lifecycle power system management, real-time monitoring and early warning of AI energy consumption models, digital twins, and multi-objective algorithm-based optimal scheduling. For underground mines, key efforts include applying high-efficiency electric-driven roadheaders and shearers in excavation and mining faces, energy-saving transformation of existing electromechanical equipment, waste heat recovery and utilization, comprehensive utilization of full-concentration gas extraction, new energy development in mining areas, and clean transformation of transportation. For open-pit mines, key measures cover using electric excavators for excavation and photovoltaic-directly-powered dump trucks, and reducing energy consumption in coal washing through intelligent dry separation systems.The multi-energy complementary smart system promotes efficient energy circulation and comprehensively supports the zero-carbon transformation of mines.

联系人:宋晓波 联系电话:18610287253