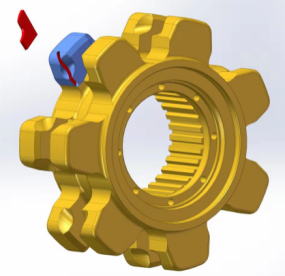

链轮切片

该链轮采用与专业机构研发的专用材料,融合多道先进工艺打造:通过电渣重熔细化晶粒、减少杂质,以压力锻造将强度及韧性提升至 1300MPa 以上,依托全自动数字化产线实现 IT6 级以上加工精度;搭配数字化调质与仿形控制热处理,全程参数可追溯,达成 “基体柔韧、工作部位耐磨” 的平衡效果,再经高精度链窝淬火,确保链窝硬度≥HRC55、淬硬层≥15mm。产品可与链条高效协同,显著提升自身耐磨性与抗疲劳性。

The sprocket is crafted using specialized materials developed in collaboration with professional institutions and incorporates multiple advanced manufacturing processes: The grain structure is refined and impurities are reduced through electroslag remelting; its strength and toughness are elevated to over 1,300 MPa via press forging; and processing precision exceeding IT6 grade is achieved through a fully automated digital production line. Paired with digital tempering-quenching and contour-controlled heat treatment featuring full parameter traceability, it achieves a balanced performance of "ductile matrix and wear-resistant working surfaces." Subsequent high-precision chain pocket quenching ensures a hardness of ≥HRC55 and a quenched layer depth of ≥15 mm. The product demonstrates efficient synergy with chains, significantly enhancing its wear resistance and fatigue resistance.

联系人:曾喜 联系电话:18295022107