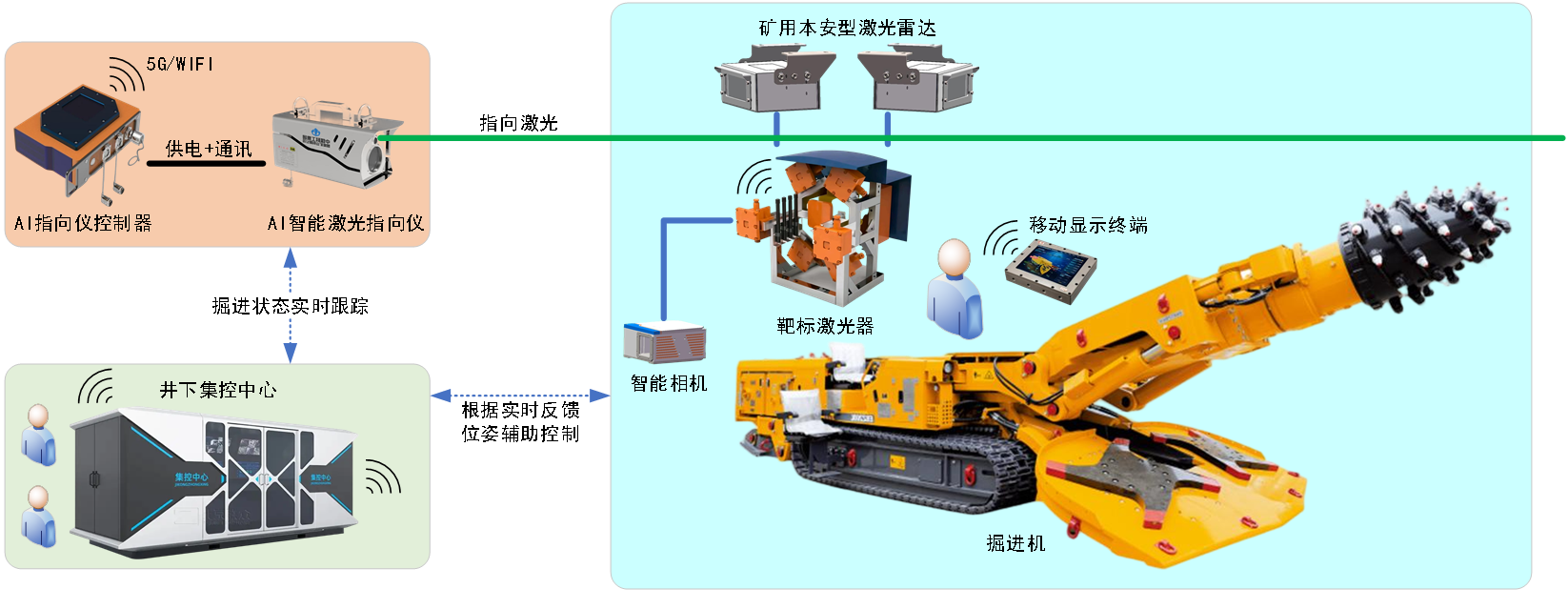

智能掘进导向系统

掘进导向系统能够有效解决巷道成型精度不足、掘进速度缓慢、掘进司机劳动强度高及迎头减员困难等问题。该系统由激光指向仪、指向仪控制器、靶标、矿用本安型激光雷达以及移动显示终端等部分组成。通过激光指向仪内置的智能视觉系统对靶标进行实时目标跟踪,基于摄影测量原理实现掘进机机身位置和姿态的测量;同时通过矿用本安型激光雷达实现巷道三维建模。系统根据位置和姿态数据显示计算后的偏转信息,传递至掘进机控制模块辅助实现自动化掘进;同时给出位置姿态等多参数调整建议,掘进司机及远端控制台可根据调整建议及实时视频/点云成像,实时调整位置,实现掘进机的本地及远程辅助精准掘进作业。指向仪在粉尘浓度≥200mg/m³条件下,可持续导航300m,位置测量精度≤2cm,姿态测量精度≤0.2°填补了行业空白。

The tunneling guidance system effectively addresses issues such as insufficient roadway forming accuracy, slow tunneling speed, high labor intensity of tunneling drivers, and difficulty in reducing personnel at the working face.

The system consists of a laser pointer, a pointer controller, a target, a mine-used intrinsically safe laser radar, and a mobile display terminal. It performs real-time target tracking of the target through the intelligent vision system built into the laser pointer, and measures the position and attitude of the roadheader body based on the photogrammetry principle; at the same time, it realizes 3D modeling of the roadway via the mine-used intrinsically safe laser radar.

The system displays the calculated deflection information based on position and attitude data, which is transmitted to the roadheader control module to assist in achieving automated tunneling. Additionally, it provides adjustment suggestions for multiple parameters such as position and attitude. Tunneling drivers and remote control consoles can adjust the position in real time according to the adjustment suggestions and real-time video/point cloud imaging, realizing local and remote auxiliary precise tunneling operations of the roadheader.

The pointer can continuously navigate 300 meters under the condition of dust concentration ≥ 200mg/m³, with a position measurement accuracy of ≤ 2cm and an attitude measurement accuracy of ≤ 0.2°, filling the gap in the industry.

联系人:丁旭阳 联系电话:18834284585