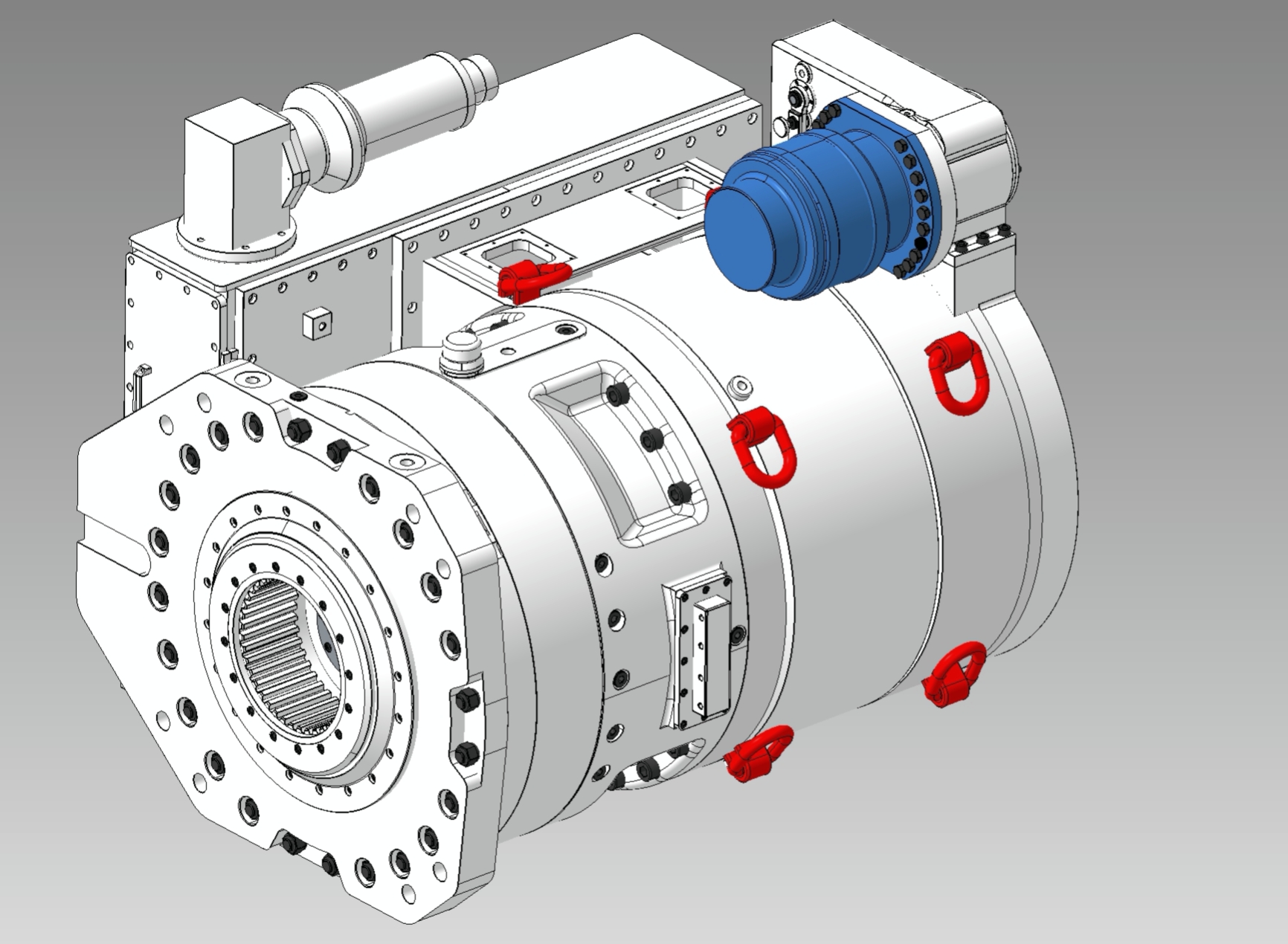

10kV供电刮板输送机用1600kW减速永磁驱动装置

天地奔牛研制的10kV供电刮板输送机用1600kW减速永磁驱动装置,集成低速永磁电动机、变频器、减速器以及紧链装置一体化设计,采用10 kV高压直供技术、三电平拓扑及软启动技术、高功率密度技术以及精密齿轮传动技术等,产品具有体积小、启动扭矩大且电流小、绿色高效等特点。可以有效简化供电调压系统、实现长距离稳定供电、大幅降低供电的压降与线损等,提升综采工作面整体效能。

The 1600 kW reduced-speed permanent magnet drive device for 10 kV power-supplied scraper conveyors, developed by Tiandi Benniu, features an integrated design that combines a low-speed permanent magnet motor, a frequency converter, a reducer, and a chain tensioning device. It employs technologies such as 10 kV high-voltage direct power supply, three-level topology and soft-start technology, high power density technology, and precision gear transmission technology. The product is characterized by its compact size, high starting torque with low current, and eco-friendly and efficient performance. It can effectively simplify the power supply voltage regulation system, enable stable long-distance power supply, significantly reduce voltage drops and line losses in the power supply, and enhance the overall efficiency of the fully-mechanized mining face.

技术参数

1.性能特点

(1)体积小:行业内最小体积的永磁驱动装置,体积与同功率3300V减速永磁驱动装置相近,可以直接替换同功率的减速永磁驱动装置和常规动力部。

(2)高功率密度行星减速器:箱体采用联合研发的高强度球铁材料,抗拉强度≥450MPa;齿轮材料与国内知名特种钢厂合作研发,经热处理后材料的抗拉强度≥1400MPa,齿面硬度稳定保持在HRC60-62;齿轮采用硬切和磨齿工艺,达到5级精度;创新设计了重叠式紧凑型行星传动单元以及内置铜质翅片管冷却器。减速器的效率≥96%,平衡油温控制在80℃以下。

(3)高效节能:采用10 kV高压直供,无需变压器等供电设备,从源头简化井下供电调压系统。变频器采用专有技术进行设计,与同类产品相比,体积缩小60%,发热量降低20%。

2.技术参数

(1)额定功率(kW):1600

(2)供电电压(V) :10000

(3)供电频率(Hz) :50

(4)输出转速(r/min) :34.1

(5)外形尺寸(mm):2208 × 1770 × 1260

联系人:孔进 联系电话:15226221785