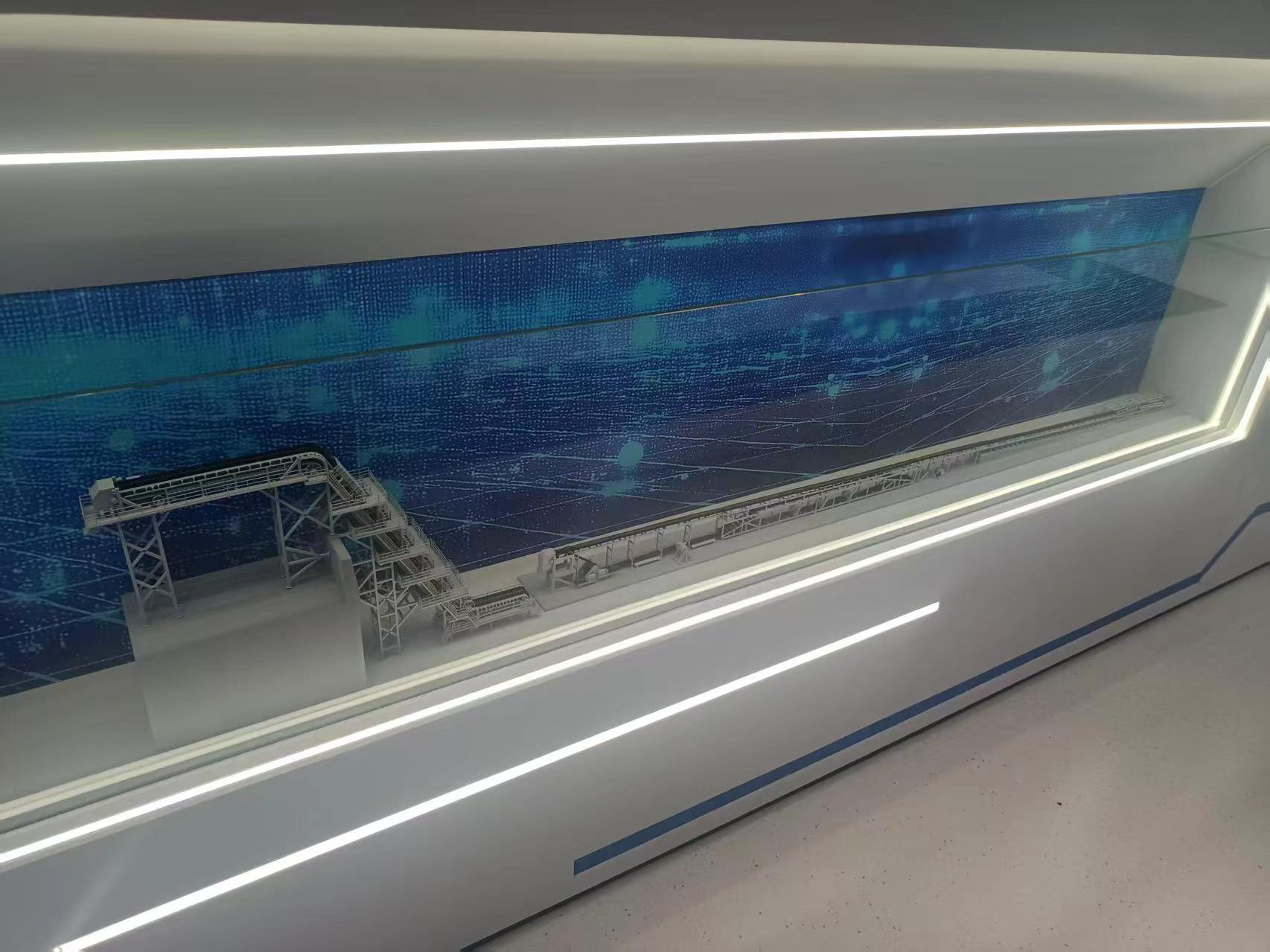

快速掘进后配套连续输送系统

连续带式输送机攻克了连续输送机不断延伸造成动力学问题复杂、隧(巷)道水平弯曲导致连续输送机机身及机尾易跑偏、空间狭小条件下600m大容量储带等技术难题。最长运输距离达到17000米。

垂直提升带式输送机解决了粘性物料清扫、机尾无磨损自清式漏渣收集与输送、大提升高度波纹挡边输送带防跑偏等技术难题,和隧洞深井施工传统提升方式相比,输送效率提升5倍以上。最大运输高度达到83米,垂直段角度可适应60~90°。

The continuous belt conveyor has overcome technical challenges such as the complex dynamic problems caused by the continuous extension of the continuous conveyor, the easy deviation of the continuous conveyor body and tail caused by the horizontal bending of the tunnel (roadway), and the 600m large capacity storage belt under narrow space conditions. The longest transportation distance reaches 17000 meters.

The vertical lifting belt conveyor solves technical problems such as cleaning viscous materials, self-cleaning slag collection and transportation without wear at the tail of the machine, and preventing deviation of the large lifting height corrugated edge conveyor belt. Compared with the traditional lifting method for tunnel deep well construction, the conveying efficiency is increased by more than 5 times. The maximum transportation height reaches 83 meters, and the vertical section angle can adapt to 60-90 degrees.

联系人:陈卫峰 联系电话:13321909806