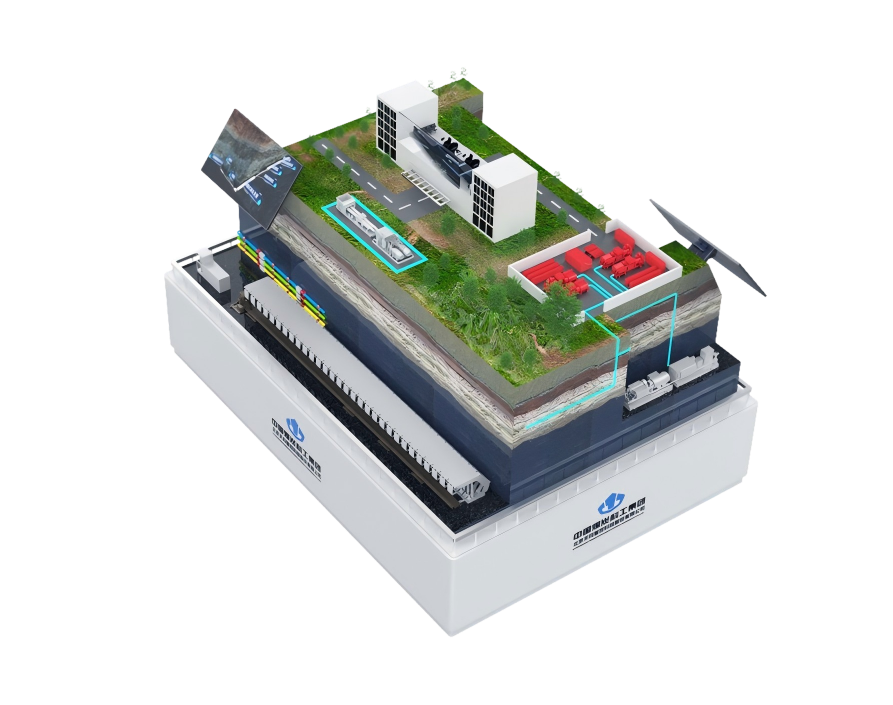

煤矿多场景智能供液解决方案

展示了天玛智控在供液领域的成套解决方案。

1.远程大流量集成供液系统:系统通过构建多盘区工作面超远距离智能供液系统整体构架,应用基于多变量的电液控制模型,解决了不同高差工作面同时生产下压力不平衡和供液不足的难题。基于系统压力波动进行削峰填谷,实现了回液管路振动抑制与回液被压治理。远程集中供液模式将矿井内各工作面所需的乳化液集中在井下固定硐室内统一配制、储存、过滤和加压,再通过管道网络远程、精准、按需输送到各个用液点,从单一功能走向系统集成,,有力支撑了煤矿安全、高效、智能、绿色开采目标的实现。

2.智能控制策略:通过构建供液系统与液压支架系统之间的供液-用液匹配响应机理模型,建立高精度数字孪生系统,实现对用液需求的超前识别与预测。以变频调节与电磁卸载作为核心调控手段,动态优化供液过程,确保液压支架系统获得持续、稳定、及时的供液支持。该策略有效突破了传统经验型控制模式的局限,显著抑制供液波动,在实现能耗大幅降低的同时,全面提升系统整体能效。

3.煤矿压裂解决方案:首创变频压力调节技术,攻克了压裂各阶段流量和压力需求差异化及快速突变的难题,实现全过程的实时精准控制。此外,低振低噪的设计改善了井下工作环境,而远程自动逻辑控制则有效减少了井下作业人员,提升了安全性。电驱压裂橇具有集成撬装、智能控制、高效节能的特点,电驱压裂橇采用纯电驱动,从源头上实现了零排放。其集成撬装设计带来了高度的模块化和快速部署能力,能大幅缩短矿山现场的施工准备周期,为低渗透煤层增透,冲击地压防治等复杂地质条件改造场景提供“外科手术级”的解决方案,实现煤层增透、瓦斯治理、冲击地压防治的智能化升级。

Smart Remote Liquid Supply System Solution Display Platform:

1.Remote High-Flow Integrated Liquid Supply System: By constructing the overall framework of an ultra-long-distance intelligent liquid supply system for multi-panel working faces and applying a multivariable-based electro-hydraulic control model, the system solves the problems of pressure imbalance and insufficient liquid supply during simultaneous production of working faces with different height differences. It performs peak shaving and valley filling based on system pressure fluctuations, achieving vibration suppression of return liquid pipelines and control of return liquid back pressure. The remote centralized liquid supply mode centrally prepares, stores, filters, and pressurizes the emulsion required by each working face in the mine in a fixed underground chamber, and then remotely, accurately, and on-demand delivers it to each liquid consumption point through a pipeline network. Transforming from a single-function system to a system-integrated one, it strongly supports the realization of coal mine safety, high efficiency, intelligence, and green mining goals.

2. Intelligent control strategy: By constructing a matching response mechanism model between the fluid supply system and the hydraulic support system, a high-precision digital twin system is established to achieve advanced recognition and prediction of fluid demand. With variable frequency regulation and electromagnetic unloading as the core control methods, the fluid supply process is dynamically optimized to ensure that the hydraulic support system receives continuous, stable, and timely fluid supply support. This strategy effectively breaks through the limitations of traditional experience-based control modes, significantly suppresses fluid supply fluctuations, and while achieving a substantial reduction in energy consumption, it comprehensively enhances the overall energy efficiency of the system.

3.Coal Mine Fracturing Solution: The innovative variable frequency pressure regulation technology overcomes challenges related to fluctuating flow and pressure demands across different fracturing stages, enabling real-time precise control throughout the entire process. Additionally, the low-vibration and low-noise design improves the underground working environment, while remote automated logic control effectively reduces the number of personnel required underground, enhancing safety. The electric-driven fracturing skid, characterized by its integrated skid-mounted design, intelligent control, and high energy efficiency, operates solely on electric power, achieving zero emissions at the source. Its modular skid-mounted design offers high modularity and rapid deployment capabilities, significantly shortening the preparation period for on-site mining operations. This solution provides a "surgical-grade" approach for enhancing permeability in low-permeability coal seams and managing complex geological conditions such as rock burst prevention. It facilitates intelligent upgrades in coal seam permeability enhancement, gas control, and rock burst prevention.

联系人:张飞超 联系电话:13911703271