MG450/1100-WD

适应f5~f7煤岩保护层薄煤层采煤机-MG450/1100-WD

该型采煤机首创了正常骑溜式和悬机身式两种类型采煤机的优点,采用常规机身+H型摇臂的布置结构,有效解决了装机功率、过煤空间、运行稳定性之间的矛盾问题;开发了针对性的减振策略和匹配的减振方案,提升了电控系统的工作稳定性;整机设计裕度系数大、可靠性高、智能化配置完善,是薄煤层工作面高智能、高效率开采采煤机,满足最低1.3m采高要求,可实现硬度f5~f7硬岩截割。

该-MG450/1100-WD机型已成功适用于平煤神马集团十矿,在全岩条件下,全月顺利开采239米,刷新集团同等岩石条件下推进历史记录。

Adapt to f5~f7 coal rock protective layer thin coal seam shearer-MG450/1100-WD This type of shearer pioneered the advantages of two types of shearers: normal riding and suspended body. It adopts a conventional body H-shaped rocking arm layout, effectively solving the contradiction between installed power, coal passing space, and running stability. It has developed targeted vibration reduction strategies and matched vibration reduction schemes, which have improved the working stability the electrical control system. The overall design has a large margin coefficient, high reliability, and a perfect intelligent configuration, which is a high-intelligence and high-efficiency shearer thin coal seam faces. It meets the requirement of a minimum 1.3m mining height and can achieve hard rock cutting of f5~f7.

The MG50/1100-WD model has been successfully applied to the Pingmei Shenma Group's No.10 mine. Under the condition of full, it has successfully mined 239 meters smoothly in a month, setting a new historical record for the same rock condition advancement in the group

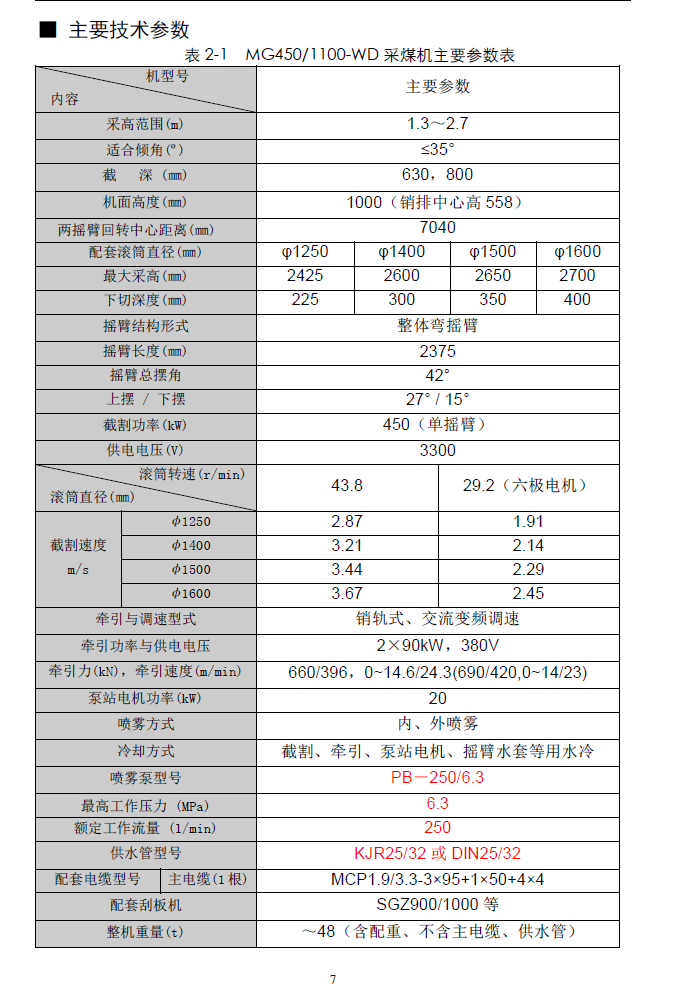

技术参数

联系人:张岳东 联系电话:13453629663